How to Choose the Right Shipping Packaging for Your Products?

Choosing the right shipping packaging is crucial for businesses. Shipping packaging protects products during transit. It affects customer satisfaction and costs.

Consider various factors when selecting your packaging. The size, weight, and fragility of your products matter. Appropriate materials enhance safety. For instance, use bubble wrap for fragile items. However, it can be costly and may not always be eco-friendly.

Neglecting packaging can lead to issues. Damaged products mean unhappy customers. Returns increase costs and waste time. Reflect on your shipping packaging choices. Are they effective and sustainable? Finding balance in protection and cost is key.

Understanding Different Types of Shipping Packaging Materials

When selecting shipping packaging, it's vital to understand the material types available. Cardboard boxes are a popular choice. They provide flexibility and strength for various items. Some cardboard holds moisture well, while others do not. This could affect your products during transit.

Bubble wrap offers additional protection for fragile items. It's lightweight and cushioned, ideal for electronics or glassware. However, it can create waste if not disposed of properly. Using biodegradable alternatives might be a better choice moving forward.

Polyethylene bags are another option. These bags are waterproof and lightweight, which helps reduce shipping costs. Yet, they may offer less protection against impact. Consider double wrapping more fragile items. Striking the right balance between cost and protection is essential. Keep experimenting with different materials to find what works best for your products.

Shipping Packaging Material Comparison

This chart compares the cost of different shipping packaging materials, providing insight into which option may be the most economical for your products.

Evaluating Product Dimensions and Weight for Packaging Selection

When selecting packaging, consider the dimensions and weight of your products. Accurate measurements are crucial. A package that is too large may lead to excessive shipping costs. On the other hand, a package that is too small risks damaging your items during transit. Measure length, width, and height carefully. Weight is just as important. Heavier items require sturdy packaging to ensure safety.

Think about the shape of your products. Irregular shapes may need custom packing solutions. They might not fit traditional boxes well. This can complicate the packing process. Utilize cushioning materials to fill empty spaces. It’s essential to protect the items without adding unnecessary weight. Reflect on your choices; bad packaging can lead to unhappy customers.

Evaluate the materials you use. Are they eco-friendly? Heavy-duty options may offer more protection, but they can be costly. Lighter materials can reduce shipping expenses, but may not provide adequate protection. A balance is essential. Keep in mind the environmental impact of your choices. Your packaging reflects your brand values. Rethink packaging decisions whenever possible to improve efficiency and sustainability.

Assessing Protection Levels: Cushioning and Structural Integrity

When selecting shipping packaging, consider how well it protects your products.

Cushioning materials like bubble wrap or packing peanuts can absorb shocks during transit.

The right cushioning prevents fragile items from breaking. However, overuse can result in wasted space and excess costs. Aim for a balance: enough protection without going overboard.

Structural integrity is equally important. The outer box should withstand stacking and handling.

A flimsy box can tear or collapse. Test different box materials to find what works best for your items.

Cardboard may suffice for lighter goods, but sturdier options are needed for heavier items.

Think about the shape and weight of your products. A snug fit reduces movement, minimizing the chance of damage.

Consider customizing the size of your packaging to suit your products better.

Remember, shipping packaging reflects your brand. Take time to evaluate your choices, and adjust when necessary.

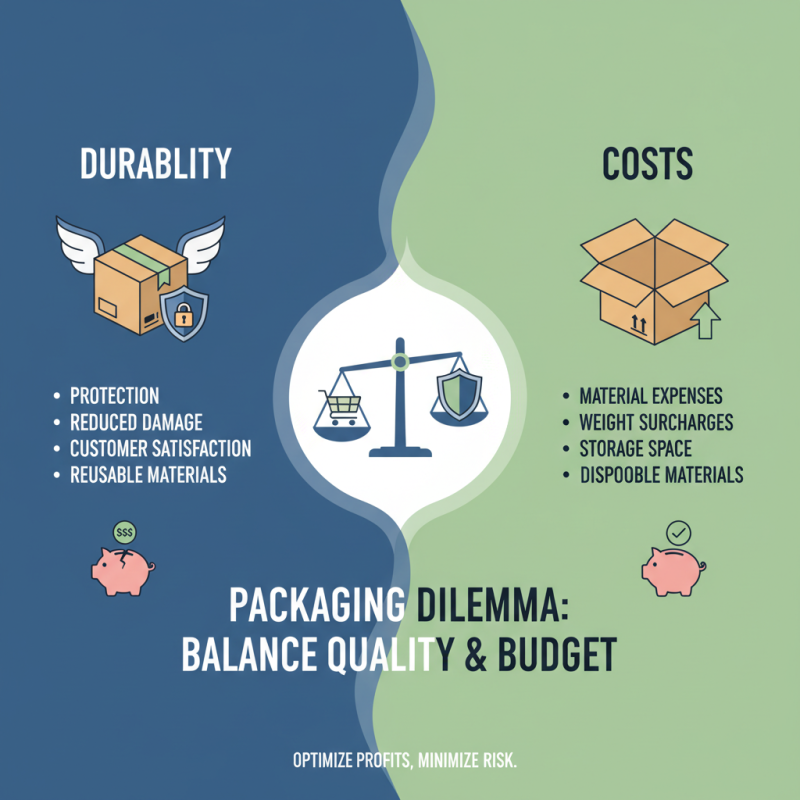

Cost Considerations: Balancing Budget with Packaging Quality

Choosing the right shipping packaging is not just about aesthetics. It's also about managing costs effectively. Quality packaging can protect products, reducing damage during transit. However, premium packaging materials can inflate shipping costs. This creates a challenge for businesses. They must balance durability with budget constraints.

Consider the materials you choose. Cardboard is often a cost-effective choice, yet it may not suit all products. Fragile items might require padded envelopes or custom boxes. These options may be pricier, but the investment pays off by minimizing returns and customer complaints. Often, businesses overlook the long-term benefits of higher quality packaging.

It's crucial to experiment and assess the impact of packaging decisions. Analyze shipping data to identify patterns in product damage. This can reveal whether cheaper packaging is worth the risk. Sometimes, saving a few cents on packaging leads to higher costs later. Reflecting on these choices can help you find that sweet spot between cost and quality.

Sustainability in Shipping Packaging: Eco-Friendly Options to Consider

When choosing shipping packaging, sustainability plays a crucial role. More consumers are demanding eco-friendly options. This shift influences how companies select their materials and designs. Cardboard, for instance, is recyclable and biodegradable. It's a versatile choice for many products.

Plastic can be detrimental to the environment. However, some companies offer bio-based alternatives. These innovative options degrade faster than conventional plastics. Yet, these alternatives often come at a higher cost. Not every business can afford to make this investment.

Also, consider the size of the packaging. Overly large boxes waste materials and space. This can lead to more emissions during transport. A tight fit reduces the amount of filler needed. Optimizing packaging size is both practical and sustainable. Balancing cost and ecological impact remains an ongoing challenge for many businesses.

Related Posts

-

Discover Exceptional Shipping Packaging Solutions from Top Manufacturing Facilities in China

-

What is Packaging Parcel? Understanding Types and Benefits for Your Business

-

Top 10 Parcel Packaging Manufacturers from China at the 137th Canton Fair

-

How to Choose the Right Packaging Parcel Solution for Your E-Commerce Business Success

-

2025 Trends in Shipping Packaging: Top Innovations for Sustainable Solutions

-

How to Select the Best Packaging Parcel Solutions for Your Business Needs